-

+8615890068607

+8615890068607

-

+8615890068607

+8615890068607

-

nanbeiinstrument@nanbei-china.com

nanbeiinstrument@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

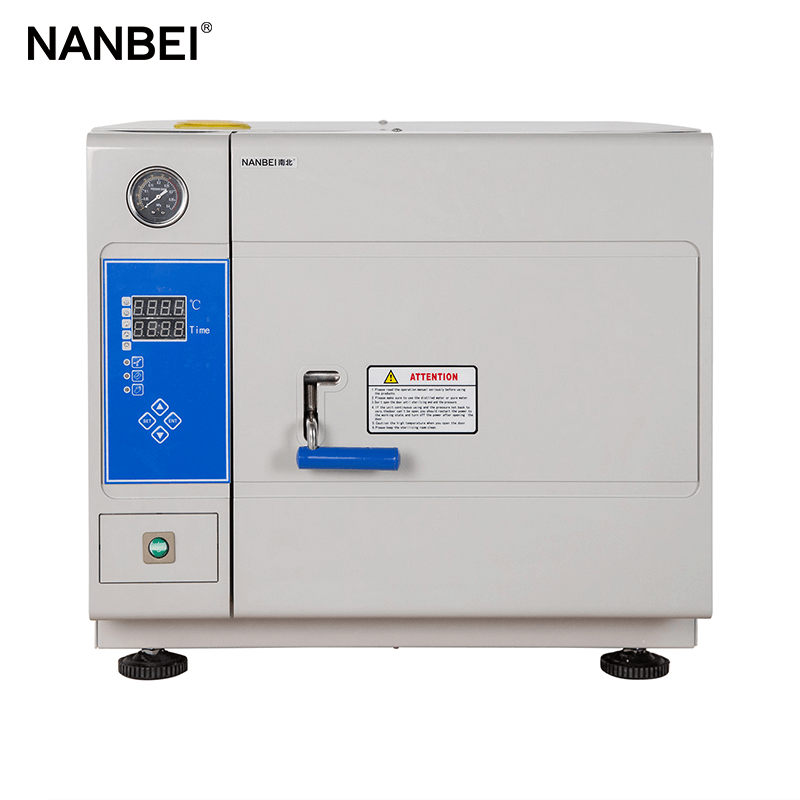

High pressure steam sterilization is a commonly used sterilization method in experiments, using the latent heat released by high pressure and high heat steam for sterilization, which is a reliable and effective sterilization method at present. High-pressure steam sterilizer is applicable to the sterilization of instruments, dressings, utensils, liquid medicine, culture media and other articles that are resistant to high temperature, high pressure and moisture.

1. By volume and shape:

Table top steam sterilizer: < 30L, the sterilization chamber is barrel shaped, which can be placed on the table

Vertical sterilizer: vertical, top door, 30-150L, sterilization chamber is barrel shaped

Horizontal sterilizer: horizontal type, side door, with different capacities of less than 100 liters, 100 liters to 2000 liters, etc. The sterilization chamber is cabinet shaped or barrel shaped

2. By the way of door opening:

Top door: take and place the sterilized items from the top of the vertical pressure steam sterilizer

Side door: take and place the sterilized items from the side of the sterilizer

Double door: put the sterilized items into the sterilizer from one end, and take it out from the other side after sterilization

3. By use:

Medical sterilizer: used in hospitals, blood stations, disease control centers and other medical units

For scientific research: used in universities, research institutes, industries and other units

Steam sterilizer is applicable to medical and health undertakings, scientific research, agriculture and other units. It is also suitable for cooking equipment in plateau areas, enterprises and institutions to produce high-quality drinking water, and can also be used as high-temperature steam source equipment.

Previous: No Information