-

+8615890068607

+8615890068607

-

+8615890068607

+8615890068607

-

nanbeiinstrument@nanbei-china.com

nanbeiinstrument@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

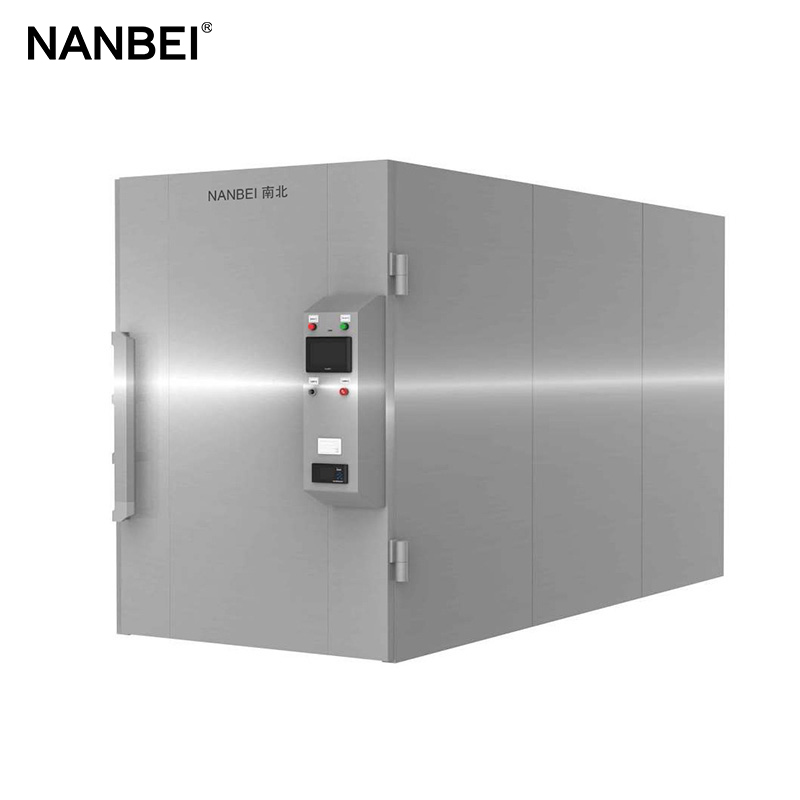

The sterilization method used by ethylene oxide sterilizer is mainly applied for heat-sensitive products or components that are not suitable for sterilization by other methods. It is commonly used in the pharmaceutical industry for the sterilization of aseptically produced components and supplies, and also for the terminal sterilization of medical devices.

Installation site requirements for large ethylene oxide sterilizer

1. Site

The ethylene oxide sterilizer should be placed in an independent workshop, and the site should be far away from the crowd. There should be no open flame operations within 30 to 50 meters of the site, and other situations that generate open flames.

2. Ventilation

The workshop where the ethylene oxide sterilizer is placed should be well ventilated, and forced ventilation should be carried out if the ventilation conditions are poor. It is strictly forbidden to seal the sterilization workshop and outdoor. The ventilation equipment installed shall be explosion-proof.

3. Lighting

The lighting and electrical switches used in the ethylene oxide sterilization workshop should be explosion-proof.

4. Fire fighting

In the ethylene oxide sterilization workshop and sterilization area, there should be obvious signs of fire prevention and no smoking. The sterilization workshop should be a key fire-fighting area where should be enough fire-fighting and extinguishing equipment.

Previous: No Information